Deburr stamped parts for burr-free assembly surfaces

Burrs on stamped parts block assembly and create scrap. At gKteso, we deburr your stamped parts automatically directly in the line, resulting in burr-free assembly surfaces without rework, allowing your parts to proceed immediately to the next process step ready for use.

Why is deburring stamped parts important?

Stamping inevitably creates burrs on cut edges, holes, or fitting surfaces. These small protrusions cause significant problems in manufacturing.

-

Assembly errors: Components do not fit cleanly, connections are misaligned, and processes are delayed.

-

Injury risk: Sharp edges cut into gloves or skin, increasing the need for protective measures.

-

Tool damage: Burrs reduce the service life of cutting inserts and clamping devices in subsequent processes.

- Optical defects: Visible burrs appear uneven and do not meet the requirements for high-quality surfaces.

- Scrap rate: Unclean sealing surfaces or damaged parts end up as scrap, driving up costs.

To guarantee the quality and stability of the process, it is crucial to define a clear deburring process for stamped parts.

What methods are there for deburring stamped parts?

Stamped parts can be deburred in various ways. The appropriate method depends on the material, geometry, and desired outcome. In practice, these methods are primarily used:

Brushing

Rotating brushes remove small burrs from surfaces and edges. They slightly round and are suitable for parts with medium surface requirements.

Grinding

Grindstones or belts remove larger burrs. This method creates smooth surfaces and is also suitable for larger areas.

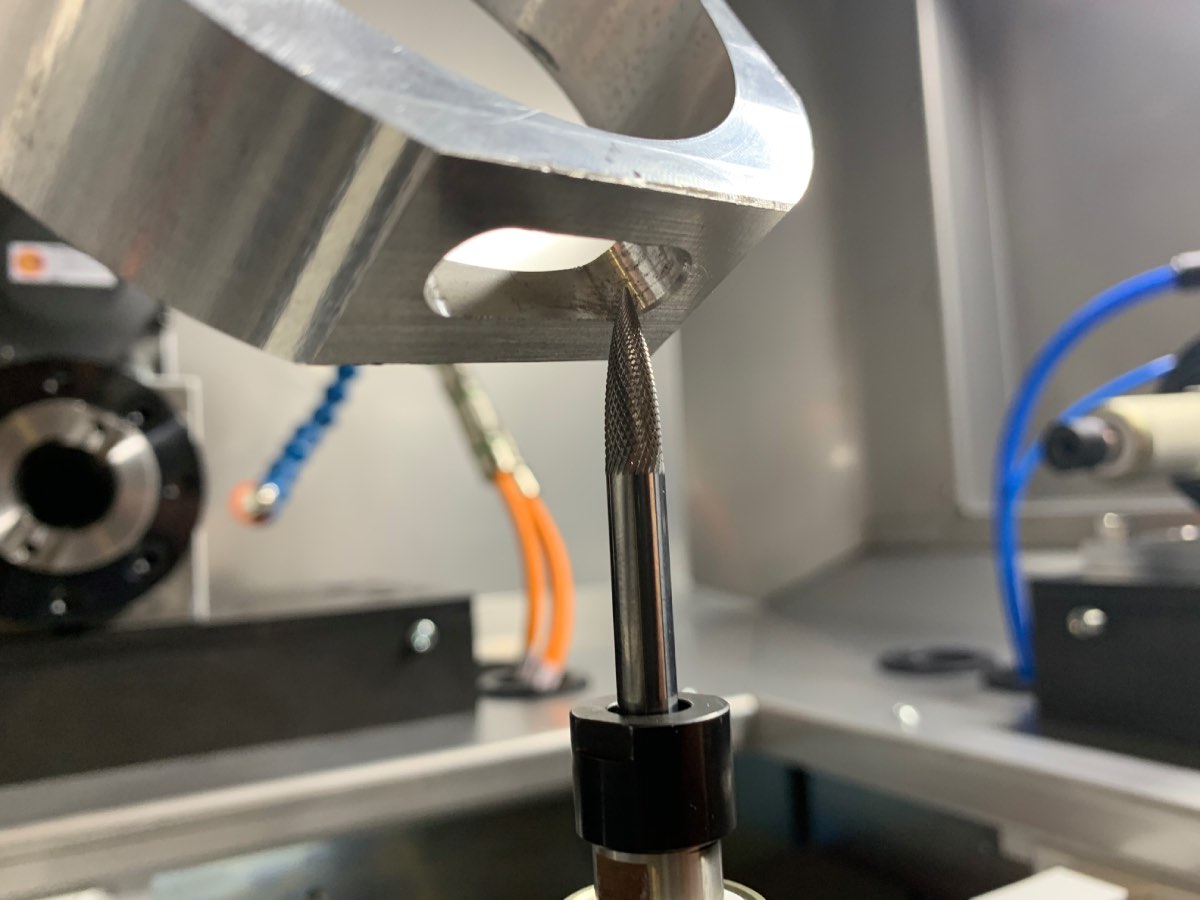

Milling

Milling cutters remove burrs on complex geometries. Deep bores or hard-to-reach areas can also be processed this way.

Countersinking

A deburring counter sink removes burrs from holes. This results in clean edges that improve sealing and fit accuracy.

Thermal deburring (TEM)

A controlled gas explosion removes burrs simultaneously from all edges and internal surfaces. The method reaches hard-to-access areas and is particularly suitable for complex stamped parts in series.

Electrochemical deburring (ECM)

An electrochemical process removes burrs without mechanically altering the base material. ECM is suitable for delicate contours, tight tolerances, and components with sensitive geometries.

Vibratory finishing (Trowalizing)

In a rotating container, grinding bodies move together with the stamped parts. This creates uniform edge patterns, improved surface structures, and a visually clean component quality.

Blasting

With glass beads, sand, or corundum, burrs can be removed over large areas. Additionally, a homogeneous surface appearance is created.

Each method has its own strengths and limitations. The decisive factor remains how the stamped parts are used in the further process. Automated solutions combine several methods in one line.

Automated deburring of stamped parts with gKteso

Our systems capture each component automatically, analyze the geometry, and choose the appropriate strategy. Tools work along defined paths, ensuring all parts receive a uniform result. This eliminates manual reworking, increases quality, and keeps cycle time stable.

Technical features of our systems

- Consistent edge patterns: Five-axis processing achieves repeat accuracy of up to 0.05 millimeters.

- Complex components: Contours, holes, and internal cutouts can be fully deburred in one operation.

- Flexible workflow: Rotary or exchange tables link loading, processing, and removal in a continuous process.

- Automated control: Scanners and touch probes monitor the processing operation and provide digital process data.

Our systems are suitable for steel, stainless steel, aluminum, and other non-ferrous metals.

What are the advantages of machine deburring?

Assembly-ready stamped parts

After deburring, all surfaces are clean and components proceed directly assembly-ready to the next process step. This eliminates time-consuming manual rework.

Planned quality

Uniform processes and documented measuring data secure approvals and facilitate audits. The system immediately detects deviations, preventing defective parts from proceeding.

Stable production flow

Parallel processes keep production in time and minimize downtime. Thus, the number of deburred parts per shift increases without requiring additional systems.

Lower cost per part

Longer tool life and less scrap reduce ongoing costs. At the same time, labor effort is reduced, as parts come assembly-ready from the machine.

Overview of our deburring machines

Together with you, we develop a tailored concept and make adjustments to the system to suit your parts and processes. We develop specific options based on drawings, photos, or sample parts.

DS Base

The DS Base is designed for small to medium series. It performs deburring, brushing, rounding, tapping, and fitting surface processing in one operation. The compact design allows easy integration into existing lines. Up to 16 stations and a working space of 500 x 500 x 300 millimeters enable the processing of many geometries. The five-axis control ensures consistent results and short setup times.

DS Integrated

The DS Integrated is developed for large quantities and varying geometries. It combines deburring, brushing, measuring, marking, and backside processing in a continuous process. A rotary or exchange table significantly reduces non-productive times. With up to 16 stations and a working area of 500 x 500 x 300 millimeters, the machine also handles complex components. It can be configured for wet or dry processing and integrated directly into lines through automatic feed systems.

How does the deburring of stamped parts work?

gKteso your partner for deburring stamped parts

Do you want to deliver stamped parts with clean edges for assembly?

We support you from analysis through sampling to series integration. This includes process planning, concept development, integration into your line, and training for your team. We consider clamping technology, material flow, and quality assurance in every project.

After commissioning, we secure your production with spare parts, service, and process optimizations. With over 30 years of experience, we develop solutions that keep your production stable and ensure your product quality in the long term.

We examine your parts, develop a concept, and show you how automated deburring of stamped parts strengthens your processes.